| Input voltage | 380V |

| Rated power | 5-10KW |

| Input gas pressure | 1.5Mpa |

| Lifting weight | 1-3T |

| Lifting height | 1-3M |

| Lifting distance | 1-2M |

| Equipment weight | 1.5T |

| Equipment size | 1800x1800x4400mm |

| Type of material | Powder or granule |

| Working humidity | 0-50RH% |

| Working temperature | -10℃-40℃ |

| Applicable material size | 0.2um-10mm |

| Handling capacity | 20T/H-30T/H |

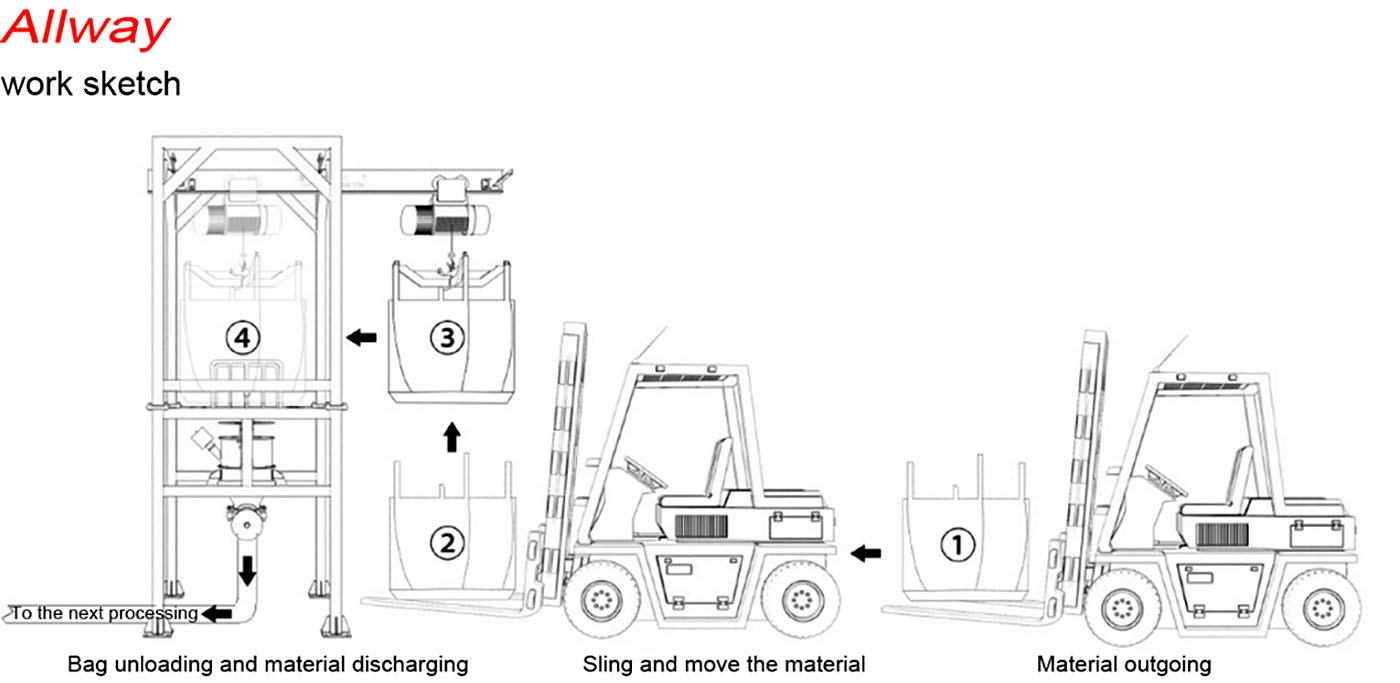

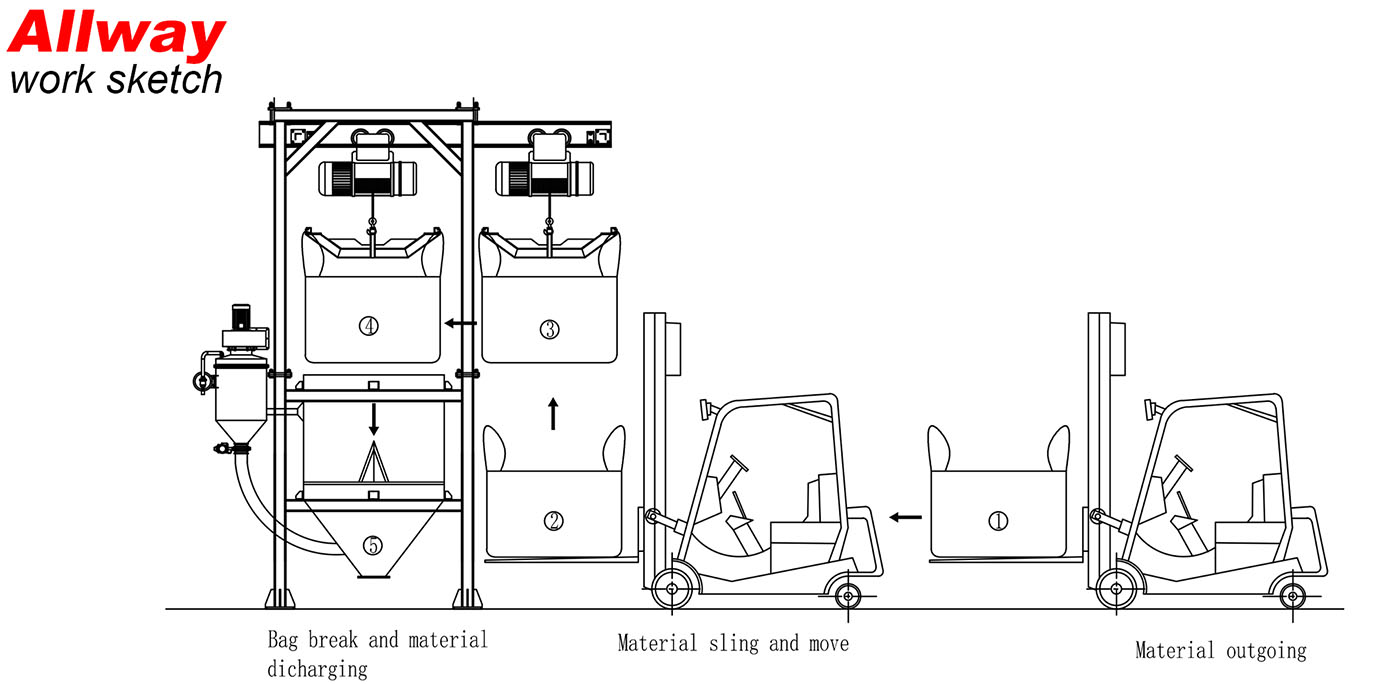

Working Sketch