Products Details

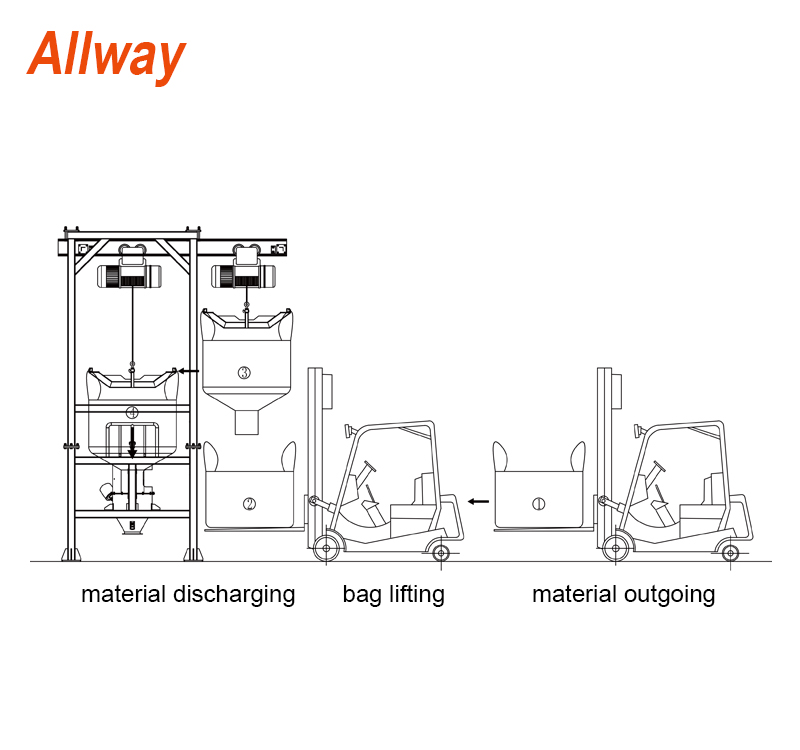

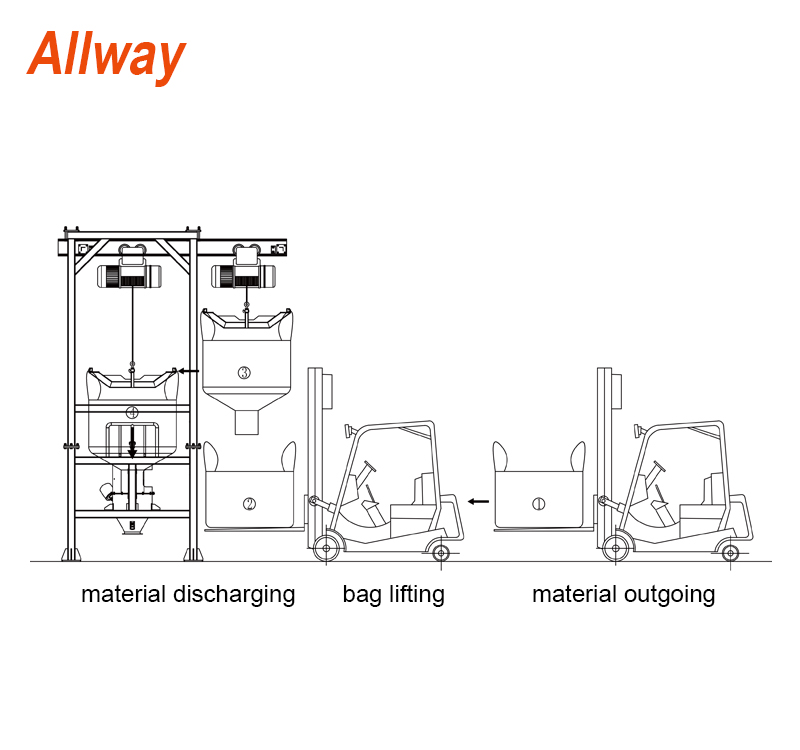

Operation instruction: 1. Workers use a forklift to carry the bulk bag material to the position of the ready lift. 2. Fix the bulk bag string to the hook and lift the bag onto the top of bulk bag unloader hopper. 3. Clamp the outlet of the bulk bag with the clamping device of the bulk bag unloader. 4. Unite the string of the bulk bag outlet and material will be discharged. 5. The machine is equipped with bag flapping device which can squeeze the material to the central when there is not much material in the bag. 6. Bulk bag unloader bag clamping type is usually fit for pellet material discharging. Equipment parameter | Working voltage | 380V |

| Power | 3-4KW |

| Air supply pressure | 0.8Mpa |

| Lifting weight | 1-3T |

| Lifting height | 1-3M |

| Lifting distance | 1-2M |

| Equipment weight | 1.5T |

| Equipment size | 1800x1800x4400mm |

| Type of material | pellet |

| Working humanity | 0-50RH% |

| Working temperature | -10℃-40℃ |

| Particle size | 2mm-30mm |

| Capacity | 20T/H-30T/H |

Salt Silo Storage,

Flexible Auger Screw Conveyor,

Big Bag Unloading Machine,

Material handling equipment,

Ribbon Blender Machine,

Bulk Bag Discharger,

Pharmaceutical Ribbon Blender,

Vacuum Pump Conveyor,

Grain Screw Conveyor,

Screw Feeder Machine,