Products Details

Horizontal ribbon mixer a.The mixing space is a horizontal U-shaped barrel with an integral screw belt shaft in the barrel body. The motor reducer is located at the end face of the main equipment. b.The mixing is stable and has little damage to the crystal. c.When the equipment is mixed, all materials are in the whole motion state, and the power requirement is high. d.The mixing time is relatively short. e.It is mainly used for mixing with powder and powder or with viscous materials. A large amount of liquid can be injected into the material when mixing. During the whole process of mixing, the material body can reflect the solid powder or viscous state, such as thickened powder, ash surface, coating, etc. Structural features of ribbon mixer a.It is composed of a U-shaped container, a ribbon stirring blade and a transmission part; b.The U-shaped long cylinder structure ensures the small resistance movement of the mixed materials (powder and semi fluid) in the cylinder. c.The positive and negative rotating screw rods are installed on the same horizontal axis to form a low dynamic and efficient mixing environment. The spiral blade is generally made of two or three layers. The outer spiral gathers the materials from both sides to the center, and the inner spiral transports the materials from the center to both sides, which can form more vortexes in the flow of materials. The mixing speed is accelerated and the mixing uniformity is improved; d.Horizontal ribbon mixer is a new mixing equipment with high efficiency, high uniformity, high loading coefficient, low energy consumption, low pollution and low crushing. e.It can be used for mixing powder and powder, powder and liquid, especially for paste, viscous or heavy materials (such as putty, stone paint, metal powder, etc.). It is widely used in pharmaceutical, food, pesticide, dye, chemical, plastic, ceramic, coating, putty, mortar and other fields. Equipment Parameters | Model | Loading Ratio | Motor Power(KW) | Rotating Speed (r/min) | Feed Port(mm) | Overall Dimension(mm) | Weight(KG) |

| AWHL100L | 0.4-0.6 | 3 | 76 | | 1080*758*615 | 330 |

| AWHL200L | 4 | 66 | 1-φ400 | 1550*812*1015 | 780 |

| AWHL500L | 5.5 | 66 | 1-φ500 | 1675*1142*1300 | 955 |

| AWHL1000L | 11 | 41 | φ500 1-φ350 | 1970*1497*1550 | 1400 |

| AWHL2000L | 18.5 | 41 | 1-φ500 1-φ350 | 2480*1651*1805 | 2500 |

| AWHL3000L | 22 | 33 | 1-φ500 1-φ350 | 2880*1896*2055 | 3300 |

| AWHL4000L | 22 | 33 | 1-φ500 1-φ350 | 3026*1946*2205 | 3600 |

| AWHL5000L | 30 | 26 | 1-φ500 1-φ350 | 3518*1945*2205 | 4620 |

| AWHL6000L | 37 | 26 | 1-φ500 2-φ350 | 3905*1882*2179 | 5300 |

| AWHL8000L | 45 | 26 | 1-φ500 2-φ350 | 3978*2160*2516 | 6800 |

| AWHL10000L | 55 | 20 | 1-φ500 2-φ350 | 4500*2270*2667 | 8900 |

| AWHL12000L | 55 | 20 | 1-φ500 2-φ350 | 4486*2466*2737 | 9520 |

| AWHL15000L | 75 | 17 | 1-φ500 2-φ350 | 5363*2450*3070 | 9950 |

| AWHL20000L | 75 | 17 | 1-φ500 2-φ350 | 5670*2650*3497 | 11140 |

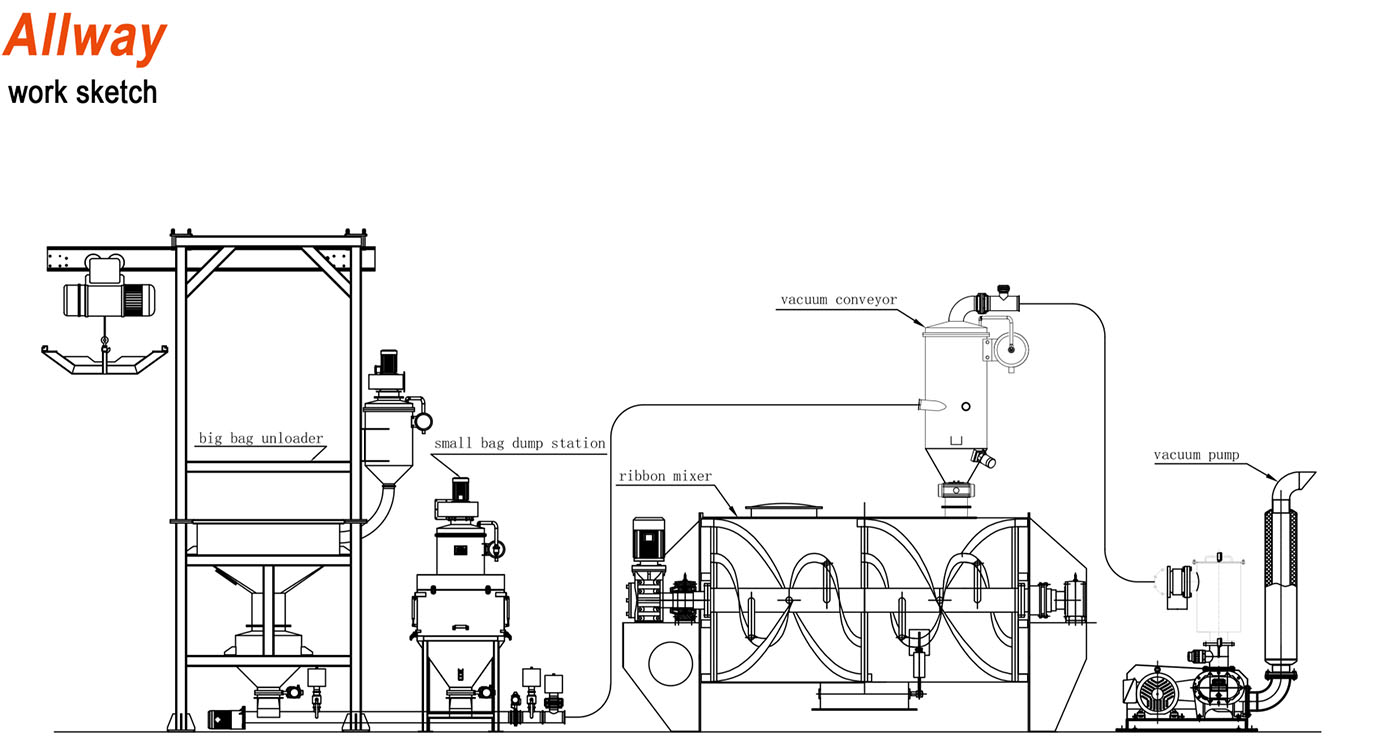

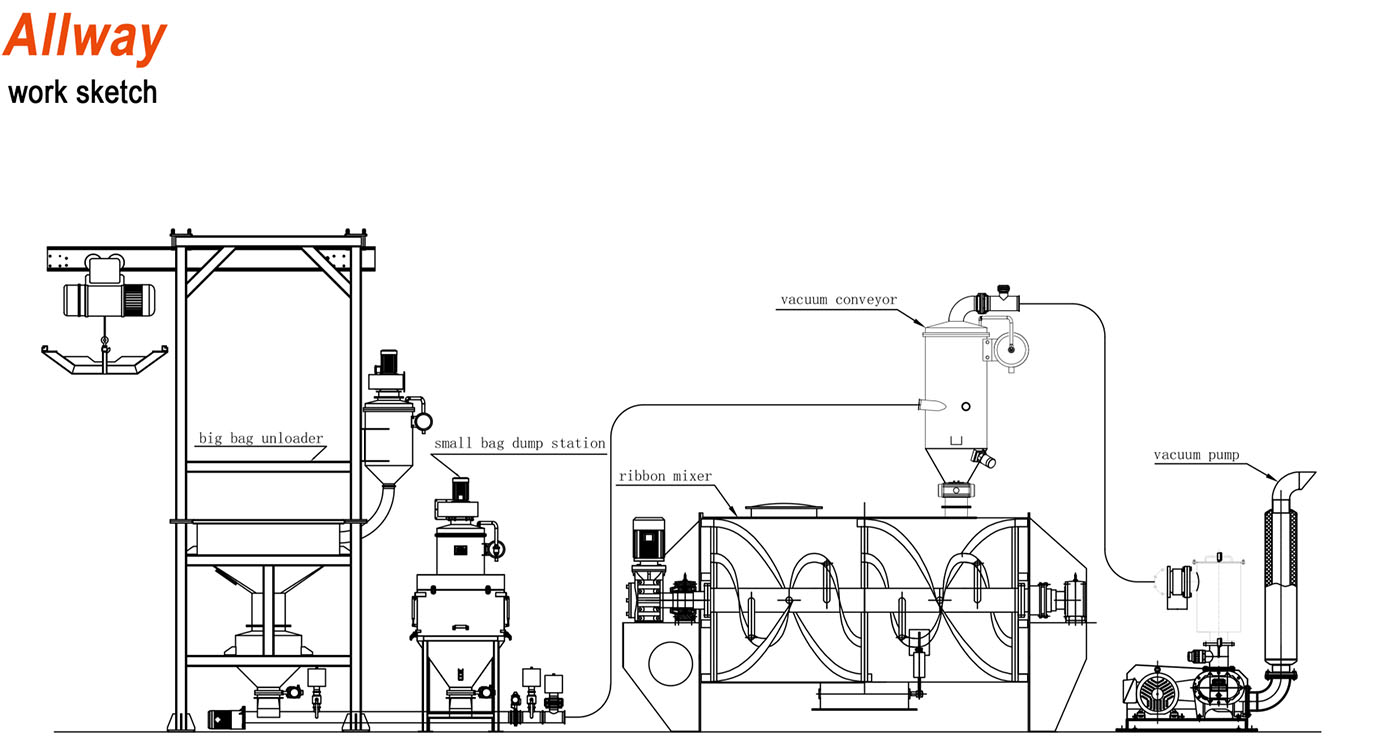

Working Sketch

Directional valve,

Salt Silo Storage,

Vacuum Grain Conveyor,

Stainless Steel Storage Hopper,

Hopper Scales,

Manual Bag Dump Station,

Bulk Bag Unloader,

Fluid control valve,

Ribbon Blender For Sale,

Gate valve specifications,